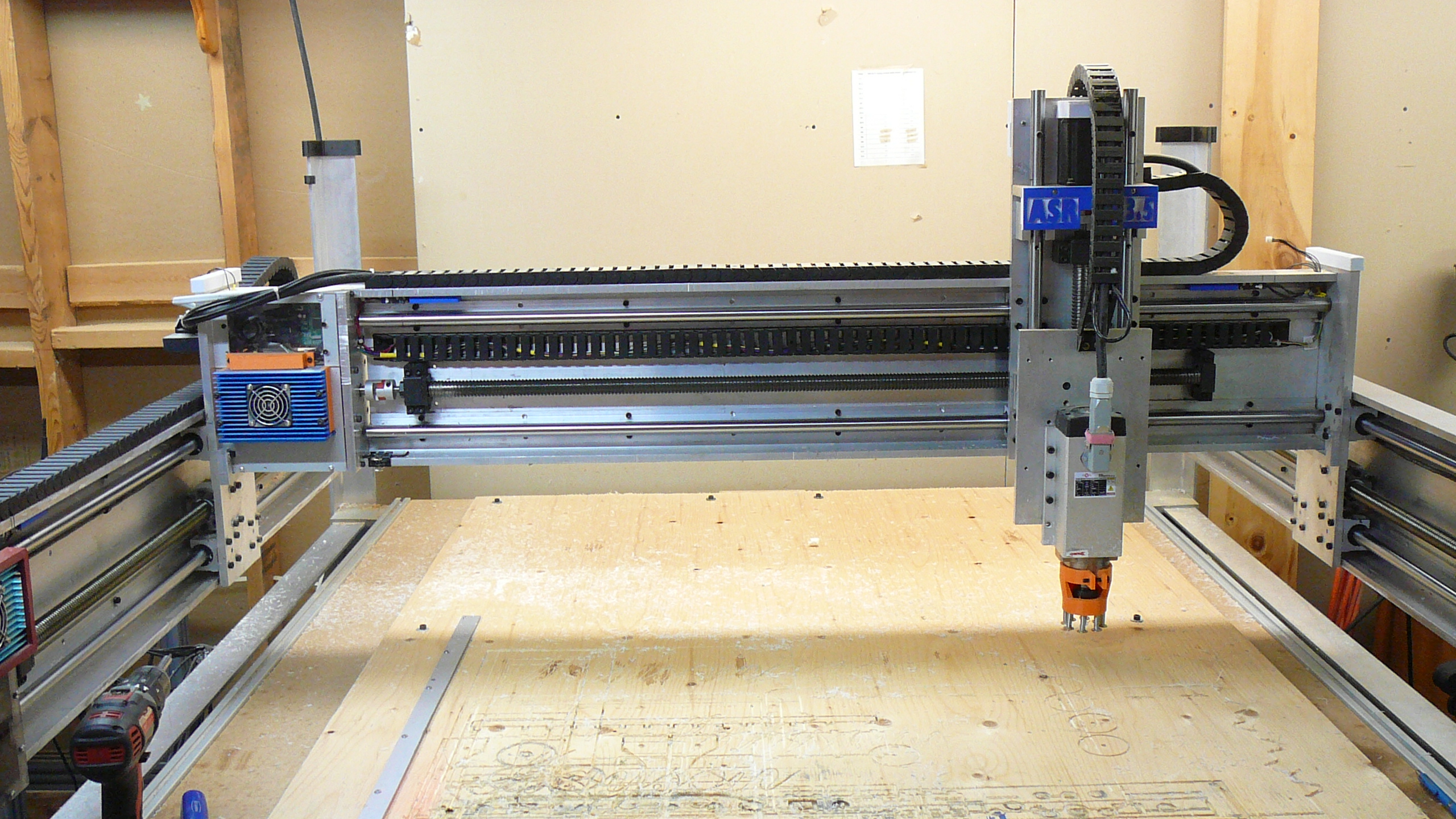

I offically retired in 2009, did a bit of traveling and decided that I needed a winter project.. wow was that an understatement. At the end of 2 years of Autocad, reading about stress and torques, buying a lot of metal, cutting and experimenting emerged a CNC router.

Its a nice size, big enough for those one-in-a-while projects and yet not so big it fills the shop.

This all started when I purchased the "XCarve" cnc router.. Its great as a hobby machine but being belt driven was prone to the belt stretching; making 2 of anything was next to impossible.

So the decision was to design and build one, and this is the results.

First was to accumulate some understanding of the stresses involved and after about 3 months of studying physics I figured I had enough to start.

The next step was to produce a set documents outlining the requirements of electrical & mechanical components which would represent something close to the final product.

Splitting the project into the various stages.